Marketing

Why are reviews important for your retail store?

Reviews guide customers as they make choices, foster trust, and can even give sales a significant lift. If your clothing...

What is Inventory Shrinkage: Causes and Prevention Tips

Wholesale

Inventory shrinkage might seem like a dull business term, but it’s something you should definitely pay attention to. If you’re managing a retail or online store, shrinkage can quietly eat away at your profits without you noticing.

But don’t stress, with a bit of understanding, you can catch it early and stop it before it causes serious damage.

In this post, we’ll explain what inventory shrinkage means, why it occurs, and how you can stop it from hurting your business. Ready? Let’s begin.

Check out: What is inventory turnover?

In simplest terms, inventory shrinkage is when the amount of stock in your inventory doesn’t match what’s actually in your store or warehouse.

This can happen if products disappear, get broken, or are not counted correctly. In an ideal situation, every item you order, sell, and track would always be in the right place. But in real life, there are many reasons why stock can go missing, and often it’s not your fault. This can reduce your profits and make it harder to plan how much stock you’ll need in the future.

Inventory shrinkage and inventory loss are connected but not the same.

Inventory shrinkage happens when stock goes missing because of theft, damage, or mistakes.

Inventory loss includes shrinkage plus products that don’t sell. In short terms, inventory loss includes both the items you lose and the ones you can’t sell anymore.

Inventory shrinkage can be a big problem for stores, and there isn’t just one reason why it happens, but it’s for sure that many factors can cause it, like theft or mistakes in keeping track of inventory. If not fixed, it can hurt the store’s profits a lot.

Let’s look at some common reasons for this problem:

Theft is a top reason for inventory shrinkage, and it can happen to both workers and customers. Employees might take items without writing them down, or change the records to make things seem like they’re gone.

If you see a lot of missing items, it could mean someone is stealing, either from your workers or your customers.

Mistakes can happen, especially when dealing with a lot of items. Sometimes workers might count wrong, type in the wrong numbers, or lose track of products.

If your inventory records don’t match what’s actually in stock, it could be because someone made a mistake, like typing the wrong amount or forgetting to count something.

Items might break while being handled, packed, or shipped, which can lead to fewer items in stock.

If you keep finding damaged items or getting returns, it might mean that the way things are handled or stored needs to be improved, which could help reduce losses.

The sooner you detect inventory shrinkage, the easier it will be to fix it. Here are a couple of tips on how to spot it before it gets out of hand:

Using technology is the best way to stop inventory from disappearing.

Tools like RFID tags, barcode scanners, and AI tools help you keep track of your stock at all times.

These tools give you quick information about how much stock you have left, tell you if something is missing, and reduce mistakes made by employees.

You can’t just check your stock once and stop. If you don’t check regularly, mistakes can happen for a long time without being noticed, causing much bigger issues.

Make sure to complete a count of all your stock once a year, but also check certain items more often, especially those that are more expensive or easy to steal.

By comparing what you count with what you have recorded, you can find out if things are missing and fix the problem. Regular checks also help your staff stay careful about how they handle and record inventory.

Your employees are the ones that manage your inventory and it can mostly depend on them on how well your inventory system works.

Good training can greatly lower losses from mistakes or stealing. Show your team how to use inventory tools, record stock changes correctly, and follow the rules you’ve set.

When workers understand how important it is to keep track of inventory and feel responsible, they’re less likely to make mistakes with stock and more likely to speak up if they see something wrong.

Reducing inventory involves using smart strategies and encouraging a responsible attitude. These useful tips can help you cut down on losses and keep your business safe.

Making your store safer is a quick and powerful way to stop shrinkage. Hire trained security staff to watch over your place, especially when it’s busy.

For instance, many clothing shops have guards near the exits to stop thieves and make sure all items are paid for before leaving. Putting in such security measures can significantly lower the chance of theft.

A strong inventory system lets you see stock levels right away, which makes it easier to find mistakes.

For example, many companies use software that works with their cash registers to update stock numbers automatically. This means if something is missing, it’s noticed right away, so you can fix the problem faster and lose less.

Limit who can go into storage rooms, warehouses, or areas with expensive items.

For instance, giving employees special codes or cards to enter these places helps you know who went in and when.

Install electronic article surveillance (EAS) gates or use RFID tagging for your inventory.

To illustrate, many stores use tags on their items. If the tag is not deactivated properly it will trigger an alarm on the exit of the store.

CCTV cameras are very useful for stopping theft. Put cameras in important places like doors, fitting rooms, and storage areas.

Cameras not only stop people from stealing, but they can also help solve problems and find out who did something wrong.

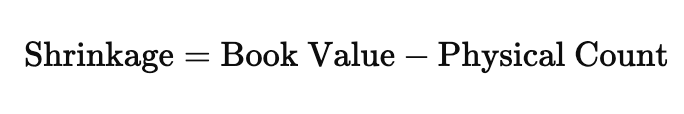

To correctly figure out inventory shrinkage, take the following steps:

1. Find the book value of inventory: This is the amount of inventory shown in your system or accounting records.

2. Do a physical inventory count: Count the items you have in your inventory.

3. Calculate the shrinkage: Subtract the physical count from the book value of your inventory.

4. Record the loss: For financial reasons, the shrinkage value should be recorded as an expense, which lowers your profit.

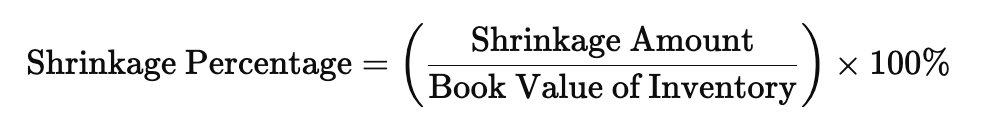

To calculate the shrinkage percentage, use the following formula:

Preventing inventory shrinkage doesn’t require superhero powers, just smart strategies and a proactive approach. If you use the right steps, you’ll protect your items and feel less stressed.

After all, watching your inventory closely is much simpler than trying to tell your accountant why your jeans keep vanishing!

What is dropshipping?